Jentner

Ihr Spezialist für

Lohngalvanik in Pforzheim

Die Jentner Group ist eines der modernsten Unternehmen für Oberflächenveredelung weltweit. Wir vereinen die Prozesssicherheit digitaler Systeme mit den Vorteilen der Handgalvanik.

Ihr Dienstleister in

Pforzheim

Unser Vorgehen vereint die Prozesssicherheit eines komplett digitalisierten Systems mit den Vorteilen der Handgalvanik. Dadurch sind wir agil und flexibel genug, um auch kleinere und individuelle Aufträge mit derselben Sorgfalt und Hingabe zu bearbeiten wie große Serienproduktionen.

Vertrauen Sie auf die langjährige Erfahrung und Kompetenz von C. Jentner GmbH und lassen Sie sich von unseren maßgeschneiderten Lösungen überzeugen.

Kontaktieren Sie uns noch heute, um Ihre Anforderungen zu besprechen und ein unverbindliches Angebot zu erhalten. Wir freuen uns darauf, Ihnen unsere erstklassigen Dienstleistungen im Bereich Oberflächenveredelung zur Verfügung zu stellen.

Entdecken sie unser

Angebot

Techniken

Gestellgalvanik

Trommelgalvanik

Bandgalvanik

Gestellgalvanik

Bandgalvanik

Trommelgalvanik

Beschichtungsverfahren

Gold

Silber

Platin

Rhodium

Palladium

Zinn

Nickel

Kupfer

Cr-III-Passivierung

Gold

Silber

Platin

Rhodium

Palladium

Zinn

Nickel

Kupfer

CR-III Passivierung

Wir bieten ihnen zahlreiche

Services

Zu diesem Zweck haben wir das Rhodium Recycling Pulver JE632 entwickelt. Es ermöglicht die Rückgewinnung von Rhodium aus gebrauchten Edelmetallbädern sowie Spülwasser in wenigen einfachen Schritten.

Unsere chemischen

Analysen

Diese Thematik bestimmte auch den Prozess unserer Entwicklungen und steigerte unser Bewusstsein für die Wiederverwertung von Rohstoffen, insbesondere das Edelmetall Recycling.

Ankauf von

Rhodium

Nachhaltigkeit durch

Recycling

Entdecken Sie unser

Team

Unsere Visionen werden getragen von den Menschen, die sie tagtäglich leben. Ohne ein starkes Team können wir die gemeinsame Erfolgsgeschichte unseres Unternehmens nicht weiter schreiben. Dies ist uns zu 100% bewusst und aus diesem Grund gilt unsere Aufmerksamkeit in gleichem Maße wie dem Absatzmarkt auch der Entwicklung der JentnerGroup als Arbeitgeber.

Wir möchten in unserem Team die maximale Expertise und höchstes Engagement für unsere gemeinsamen Ziele vereinen. Im Gegenzug geben wir das Optimum an Arbeitgeberqualität in unsere Team zurück und entwickeln uns stetig weiter.

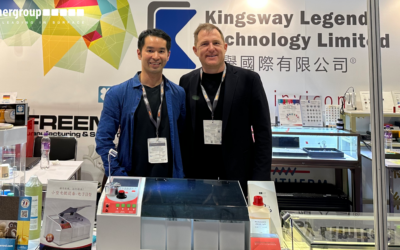

Jentner auf der HKDTC Hong Kong Jewellery Show

Jentner auf der hkdtc hong kong jewellery show!Chris Jentner zu besuch bei unserem händler in Hong kongWir möchten gerne von unserem kürzlichen Besuch bei unserem geschätzten Händler Freddie Kwok und seiner Firma Kingsway Legend Technology Limited auf der HKDTC Hong...

Internationales Forschungsprojekt

Internationales Forschungsprojekt Deutsche & südkoreanische Partner aufErkundungsreiseVom 18. bis zum 25. November 2023 fand ein aufregender Austausch zwischen deutschen und südkoreanischen Projektpartnern statt. Im Fokus stand ein wegweisendes Forschungsprojekt...

Alle aktuellen

News

Hier finden Sie alle aktuellen News rund um die JentnerGroup.

Wir halten Sie auf dem Laufenden rund um alle wichtigen Neuigkeiten um die JentnerGroup. Folgen Sie uns auch auf unseren sozialen Kanälen, um keine wichtigen Neuigkeiten mehr zu verpassen.

Das ist unser

Vorgehen

Diese klare Haltung profiliert uns als einzigartiger Partner, sowohl gegenüber unseren Kunden als auch unseren Mitarbeitern. Dass wir damit in unseren Märkten, die allesamt der Nährboden unserer Zukunftsvision sind, die zentrale Bedürfnisse der modernen Welt bedienen, lässt uns voller Begeisterung auf das blicken was die kommenden Jahre für uns bereithalten.

Eine Auswahl unserer

Kunden

Folgt bald ihr

Unternehmen?

Gerne würden wir auch Sie zu unseren Referenzen zählen! Kontaktieren Sie uns noch heute zu Ihrem galvanischen Anliegen und wir beraten Sie kostenlos und unverbindlich!

Folgt bald ihr

Unternehmen?

Gerne würden wir auch Sie zu unseren Referenzen zählen! Kontaktieren Sie uns noch heute zu Ihrem galvanischen Anliegen und wir beraten Sie kostenlos und unverbindlich!

Kontaktieren sie uns bei

Fragen

Sie sind sich unsicher, welche unserer Techniken oder Verfahren zu Ihrem Anliegen passt? Gerne beraten wir Sie hierzu auch persönlich. Nehmen Sie jetzt einfach und unverbindlich Kontakt zu uns auf.

Ihr Dienstleister in

Pforzheim

Seit über 50 Jahren steht der Name Jentner für höchste Qualität, Perfektion und Kompetenz im Bereich der Lohngalvanik & Metallveredelung.

Was Jentner ausmacht, ist das innovative und hochqualifizierte Team, welches das umfangreiche Serviceangebot und die flexible Auftragsbearbeitung erst ermöglicht. Neben dem stetig wachsenden Team wurde auch das Leistungsspektrum von Jentner in den letzten Jahren erweitert und ergänzt. Sowohl dekorative als auch technische Anforderungen der unterschiedlichsten Industriezweige können dadurch zielorientiert umgesetzt werden.

Qualität und Präzision gehen bei Jentner Hand in Hand mit einer kundenorientierten Firmenphilosophie. Moderne Galvanikanlagen ermöglichen die effiziente Umsetzung der Kundenwünsche nach Maß.

Was ist Lohngalvanik?

In kurzen Worten bedeutet Lohngalvanik das Galvanisieren im Auftrag des Kunden. Der Kunde sendet uns seine Ware zu und wir beschichten diese gemäß seinen Vorgaben. Das Galvanisieren ist also eine reine Dienstleistung. Um die Anforderungen erfüllen zu können benötigen wir die Art des gewünschten Überzugs und die erforderliche Schichtstärke. Wir beraten Sie gerne individuell und umfassend zu Ihrem persönlichen Anliegen.

Was kann ich galvanisieren lassen?

Fast alle elektrisch leitfähigen Materialen können galvanisch beschichtet werden. Es gibt nur wenige Ausnahmen, z.B. Titan, bei denen das nicht geht. Evtl. muss die Art der Beschichtung dem Grundmaterial (so wird das Material Ihrer Teile im Fachjargon genannt) angepasst werden. Manche Materialien benötigen besondere Vorprozesse oder besondere Herangehensweisen. Auch hierzu beraten wir Sie sehr gerne.

Welche Lohngalvanik-Verfahren bietet C. Jentner an?

Gestellbearbeitung

Die Gestellbearbeitung bietet die Möglichkeit, sämtliche Bauteile zu beschichten, die aufgrund verschiedener Gegebenheiten, wie z.B. Ihrer Größe, Geometrie oder Oberflächenanforderung nicht für eine Bearbeitung in der Trommelanlage geeignet sind. Die Teile hierbei einzeln in ein Galvanisiergestell eingehängt, wodurch mechanische Beschädigungen vermieden werden.

Trommelgalvanik

Die Trommelgalvanik ermöglicht es, in kurzer Zeit große Durchlaufmengen zu beschichten. Dadurch ist es nicht nur eine kostengünstige Beschichtungsvariante, sondern bietet auch attraktive Lieferzeiten für den Kunden. In der Trommel sollte allerdings nur Schüttgut beschichtet werden. Bei hochwertigen Einzelteilen würde es zu Beschädigungen kommen.

Bandgalvanik

Mit der Technik der Bandgalvanik bieten wir Ihnen eine äußerst effektive Methode, um die Haltbarkeit und Leistungsfähigkeit verschiedener Produkte zu verbessern. Durch die präzise Beschichtungstechnik werden sie langlebiger und erhalten eine hochwertige Oberfläche, die den Anforderungen der jeweiligen Branchen gerecht wird. Vereint mit unserer Arbeitsweise, geprägt von Präzision, Effizienz und Flexibilität, ermöglicht die Bandgalvanik-Technik eine erstklassige Oberflächenveredelung für unterschiedlichste Anforderungen.

Ist Jentner der richtige Dienstleister für mein Anliegen?

Mit unseren Galvanikanlagen haben wir die Möglichkeit, Kundenwünsche nach Maß effizient durchzuführen. Wir bearbeiten Kleinmengen ebenso wie Serienteile und kümmern uns hierbei sowohl um technisch-funktionale als auch dekorativ-ansprechende Oberflächen.

Jedes Anliegen wird von unserem hochqualifizierten Team individuell geprüft und bearbeitet, um Ihren persönlichen Anforderungen gerecht zu werden. Wir bei Jentner ermöglichen unseren Kunden damit ein umfangreiches Serviceangebot und eine flexible Auftragsbearbeitung.

Gerne beraten wir Sie persönlich zu Ihrem galvanischen Anliegen. Nutzen Sie dazu einfach unser Kontaktformular, oder kontaktieren Sie unsere Ansprechpartner.

Kann ich auch selbst galvanisieren?

Unsere Jentner Plating Technology GmbH bietet ein umfassendes und anwenderfreundliches Galvanoprogramm, das es Ihnen ermöglicht, auch eine selbstständige Beschichtung von Kleinteilen oder Einzelteilen vorzunehmen. So wird das Galvanisieren auch für Nichtfachleute leicht möglich. Zu unseren Kunden gehören Goldschmiede, Juweliere, Uhrmacherwerkstätten, Schulen, Universitäten, Institute und Labors, Restauratoren, Museen und Hobbymodellbauer.

Aufgrund innovativer Technologien und Entwicklungen haben wir uns weltweit zu einem der führenden Hersteller von Kleingalvanisiergeräten und Elektrolytchemikalien entwickelt und werden heute von namhaften Unternehmen in weltweit über 30 Ländern genutzt.

Wir bieten Ihnen unser gesamtes Know-How zum Selbergalvanisieren. Die benötigten Produkte können direkt in unserem Onlineshop bestellt werden. Nutzen Sie unseren Produktberater, er berät Sie zu Ihrem individuellen Vorhaben und präsentiert Ihnen die passende Produktpalette.

Ist galvanisieren umweltschädlich?

Wir von Jentner haben früh erkannt, das Umweltbewusstsein besonders im galvanischen Sektor von großer Bedeutung ist. Aus diesem Grund haben wir es uns zu unserer Aufgabe gemacht, den Energie- und Ressourcenverbrauch zu optimieren und gewährleisten eine CO2 neutrale Produktion über den gesamten Prozess.

Von Anfang an werden dabei auch unsere Lieferanten und Dienstleister in die Prozesse eingebunden und wir integrieren aktiv unsere Mitarbeiter in das Thema. Mit gezielten Wassereinsparungsmaßnahmen und Durchführung kontinuierlicher Umwelt-Schulungen wollen wir von Jentner die Umweltbelastung weiter senken. Wir sind zertifiziert nach DIN EN ISO 9001 und DIN EN ISO 14001.

Weitere Infos hierzu finden Sie auf unserer Webseite unter der Rubrik „Verantwortung“.

Für welche Branchen ist die Lohngalvanik von Jentner geeignet?

Jentner hat sich auf die Metallbeschichtung von Produkten aus verschiedenen Branchen spezialisiert. Hierzu gehören Aufträge aus folgenden Bereichen:

• Medizintechnik

• Elektrotechnik

• Automotive

• Luft- & Raumfahrt

• Labore & Institute

• Verteidigung

• Schmuck

Eine Auswahl unserer Kunden finden Sie auf unserer Startseite.

Welche Vorteile hat galvanisieren bei Jentner?

Seit über 40 Jahren stehen wir für Kompetenz, Perfektion und höchste Qualität im Bereich Metallveredelung & Lohngalvanik. Unser hochqualifiziertes Team und unser umfangreiches Angebot machen uns als Unternehmen aus. Wir erweitern stetig unser Leistungsspektrum und arbeiten kontinuierlich an innovativen Galvanikverfahren. Wir stehen für:

Einzigartige Qualität für hohe Ansprüche

Qualität und Präzision gehen bei Jentner Hand in Hand mit einer kundenorientierten Firmenphilosophie. Moderne Galvanikanlagen ermöglichen die effiziente Umsetzung der Kundenwünsche nach Maß.

Umweltbewusst & ressourcenschonend

Wir entwickeln Galvanikprodukte aus 100% recycelten Rohstoffen, um die Ressourcen unseres Planeten nachhaltig zu schonen und möchten unseren Kunden die Möglichkeit bieten, Galvanikprodukte mit ökologischer Verantwortung einzukaufen. Zudem achten wir auf darauf, den Energie- und Ressourcenverbrauch zu optimieren und produzieren CO2 neutral.

Automatisierte Handgalvanik

Mit unserer Innovation IPS 5.0 bieten wir Ihnen ein funkgesteuertes und automatisierte Oberflächenveredelung. Damit wird der gesamte Beschichtungsprozess überwacht, gesteuert und kontrolliert. Somit garantieren wir, fehleranfällige und manuelle Prozesse zu minimieren, die Materialeffizienz zu steigern und die Vor- und Nachkalkulation zu präzisieren.

Branchenspezifische Verfahren

Wir sind auditiert und erfüllen normgerechte Fertigungsverfahren in diversen Branchenbereichen. Dazu gehören heute die Bereiche Medizintechnik, Elektrotechnik, Verteidigung, Automotive, Labore & Institute und die Dekorativtechnik.

Was kostet eine Galvanisierung bei Jentner?

Der Preis gestaltet sich individuell nach Beschichtungsverfahren, Edelmetall, Bauteilgröße und Schichtstärke. Gerne erstellen wir Ihnen ein Angebot. Unser Vertriebsteam freut sich auf Ihre Anfrage.

Welche Metalle werden bei Jentner galvanisch oder auch chemisch aufgetragen?

• Gold in diversen Variationen

• Silber

• Platin

• Rhodium

• Palladium

• Schwarzruthenium

• Unedelmetalle wie Kupfer oder Nickel

• Chemisch Nickel

• Chrom-III-Passivierung

Kann sich Jentner auch um mein Verfahren kümmern?

Jedes Lohngalvanik-Verfahren ist so individuell wie die Anfrage. Unser Leistungsangebot lässt sich damit nicht pauschalisieren und unsere Seite bietet nur einen kleinen Einblick in unser gesamtes Spektrum. Daher kümmern wir uns um jedes Anliegen persönlich und erarbeiten ein individuelles Vorgehen.

Wenn Sie ein Anliegen haben, kontaktieren Sie uns gerne über unser Kontaktformular oder auch direkt unseren Ansprechpartner Herr Arnaud Bignon.